In recent years, the four-flute sawtooth drill bit has emerged as a market favorite for its innovative design and robust performance. This article delves into its core advantages, underlying technology, and ideal applications.

Why Is the Four-Flute Sawtooth Drill Bit Becoming the New Favorite?

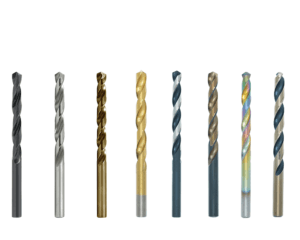

The breakthrough feature of the four-flute sawtooth drill bit lies in its innovative blade design—four main cutting edges arranged in an eccentric, staggered pattern. This unique configuration boosts efficiency by up to 300%, as the offset sawtooth cuts rapidly and reduces slippage. It not only improves hole straightness and roundness but also minimizes drill bit wander, achieving a positioning precision within 0.5mm, especially on fragile materials like full ceramic and glass. Whether you’re working on tiles, stone, or concrete, this drill bit delivers consistently cleaner and more accurate holes. This article explores its standout advantages, advanced features, and practical applications—helping you make the right choice when looking to buy multi purpose drill.

Superior Versatility and Performance

Thanks to its ultra-hard tungsten steel alloy construction and advanced wear-resistant coatings, this drill bit can handle a wide range of materials—from ceramic and marble to concrete and metal. In concrete, the dry drilling function enables direct penetration without coolant, saving up to 60% of prep time, while in hard rock, efficiency is increased by 3-5 times compared to conventional bits. Enhanced chip evacuation is achieved through a double-helical groove design, improving chip removal by 50% and preventing clogging. Together, these features extend the drill bit’s lifespan to three times that of ordinary products. The improved chip removal design prevents clogging, boosting reliability and extending tool life—making it a top product from any trusted multi purpose drill factory.

Technical Advantages and Applications

The four-flute structure provides 360° support during drilling, significantly reducing radial jump and ensuring a smooth surface finish (Ra≤1.6μm). This optimization makes it highly suitable for high-precision industrial applications such as machining hydraulic parts or aerospace engine components, as well as for deep-hole drilling where effective chip clearing is vital.

Industry Trends

Looking ahead to 2025, four-flute sawtooth drill bits are evolving towards intelligent, multifunctional designs. Innovations such as adaptive coatings and modular, quick-change components are paving the way for integrated drilling, enlarging, and chamfering operations in one tool—a trend that promises even greater efficiency and versatility in the future. So if you’re looking to buy multi purpose drill that combine precision, speed, and durability, the four-flute sawtooth drill bit is your go-to choice.

Keywords: